Product Name:

Gray Iron Brake Drum, Grey Iron Drum Brake, Iron Casting for Wheel Assembly Brake Rotor, Sand Casting Supplier, Auto Parts

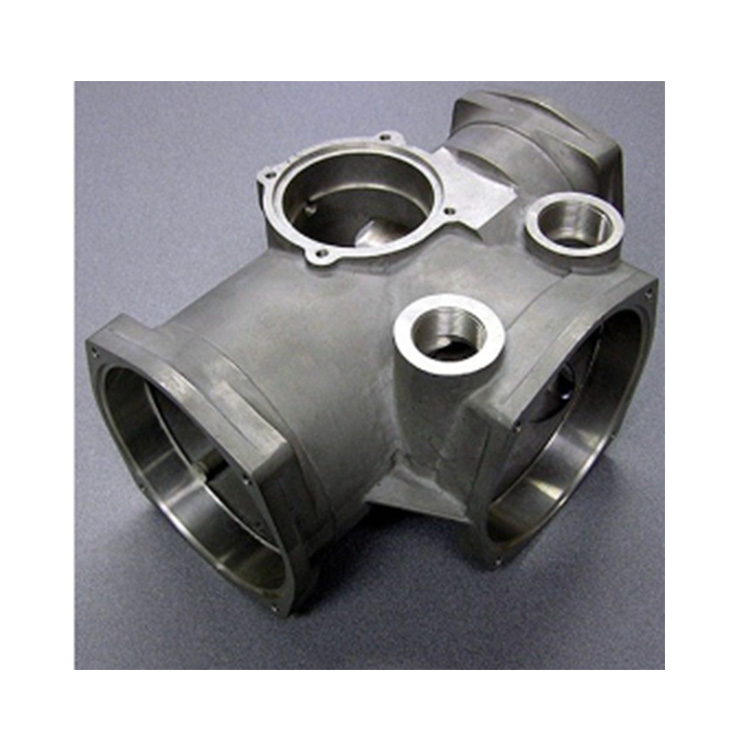

Description:

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term drum brake usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a clasp brake. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a pinch drum brake, though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum.

The brake drum is generally made of a special type of cast iron that is heat-conductive and wear-resistant. It rotates with the wheel and axle. When a driver applies the brakes, the lining pushes radially against the inner surface of the drum, and the ensuing friction slows or stops rotation of the wheel and axle, and thus the vehicle. This friction generates substantial heat.

Material Grades:

Gray Cast Iron, Grey Iron

ISO185 100 150 200 250 300

ASTMA48 NO.20 NO.25 NO.30 NO.35 NO.40 NO.45

DIN1691 GG10 GG15 GG20 GG25 GG30

EN1561 EN-GJL-100 EN-GJL-150 EN-GJL-200 EN-GJL-250 EN-GJL-300

BS1452 100 150 200 250 300

AS1830 T150 T220 T260 T300

Production Process:

Sand Casting, Automatic Molding, Machine Molding, Shell Molding, Green Sand Casting, Resin Sand Casting,

Supplier:

Gray Iron Foundry in China, Grey Iron Casting Manufacturer, Iron Foundry, China Foundry

Dandong Hengrui Foundry is producing cast iron and cast steel castings by various sand casting and precision casting processes, including Automatic Molding Line, Resin Sand Molding, Shell Molding, Manual Green Sand Cast Molding, Shell Molding, Lost Wax Investment Casting Process by water glass and silica sol materials.

We have complete quality inspection devices for Mechanical Testing and Chemical Analysis, including tensile strength, hardness, metallographic inspection, hardness, spectrometer, ultrasonic testing. ISO 9001 Certified. We can issue quality reports for all inspections.

Experience

Product Name:

Gray Iron Brake Drum, Grey Iron Drum Brake, Iron Casting for Wheel Assembly Brake Rotor, Sand Casting Supplier, Auto Parts

Description:

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term drum brake usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a clasp brake. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a pinch drum brake, though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum.

The brake drum is generally made of a special type of cast iron that is heat-conductive and wear-resistant. It rotates with the wheel and axle. When a driver applies the brakes, the lining pushes radially against the inner surface of the drum, and the ensuing friction slows or stops rotation of the wheel and axle, and thus the vehicle. This friction generates substantial heat.

Material Grades:

Gray Cast Iron, Grey Iron

ISO185 100 150 200 250 300

ASTMA48 NO.20 NO.25 NO.30 NO.35 NO.40 NO.45

DIN1691 GG10 GG15 GG20 GG25 GG30

EN1561 EN-GJL-100 EN-GJL-150 EN-GJL-200 EN-GJL-250 EN-GJL-300

BS1452 100 150 200 250 300

AS1830 T150 T220 T260 T300

Production Process:

Sand Casting, Automatic Molding, Machine Molding, Shell Molding, Green Sand Casting, Resin Sand Casting,

Supplier:

Gray Iron Foundry in China, Grey Iron Casting Manufacturer, Iron Foundry, China Foundry

Dandong Hengrui Foundry is producing cast iron and cast steel castings by various sand casting and precision casting processes, including Automatic Molding Line, Resin Sand Molding, Shell Molding, Manual Green Sand Cast Molding, Shell Molding, Lost Wax Investment Casting Process by water glass and silica sol materials.

We have complete quality inspection devices for Mechanical Testing and Chemical Analysis, including tensile strength, hardness, metallographic inspection, hardness, spectrometer, ultrasonic testing. ISO 9001 Certified. We can issue quality reports for all inspections.