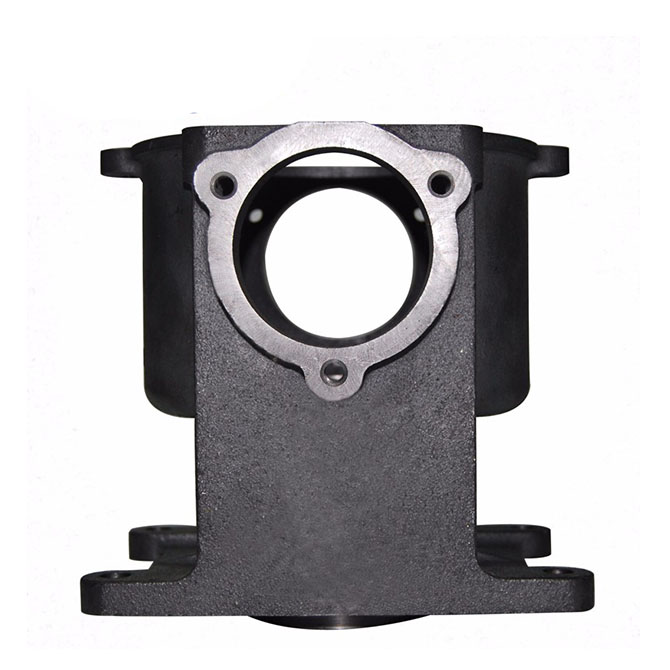

Aluminum Alloys and Aluminum Castings

Aluminum is best known for its lightweight characteristics. It is most widely used in the form of alloys which also contain varying quantities of other elements such as iron, manganese, magnesium, silicon, copper and zinc. The addition of these elements may enhance the strength of the final product, or contribute useful properties such as improved electrical or thermal conductivity. Aluminum alloys are used to manufacture components for the automotive, power transmission, electronics, computing, telecommunications industries, and more.

TYPES OF ALUMINUM ALLOYS

Wrought iron and aluminum alloys employ a specialized numerical identification system to describe the composition of wrought iron metal alloys and castings. The first digit represents the general class or series and indicates the primary alloy(s). A capital letter preceding the numerical description refers to modifications made to specific alloys. Aluminum castings end in “.0”.

In commercial specifications, aluminum alloys are usually divided into three categories: pure aluminum alloys, heat treatable alloys and non-heat treatable alloys.

Experience

Aluminum Alloys and Aluminum Castings

Aluminum is best known for its lightweight characteristics. It is most widely used in the form of alloys which also contain varying quantities of other elements such as iron, manganese, magnesium, silicon, copper and zinc. The addition of these elements may enhance the strength of the final product, or contribute useful properties such as improved electrical or thermal conductivity. Aluminum alloys are used to manufacture components for the automotive, power transmission, electronics, computing, telecommunications industries, and more.

TYPES OF ALUMINUM ALLOYS

Wrought iron and aluminum alloys employ a specialized numerical identification system to describe the composition of wrought iron metal alloys and castings. The first digit represents the general class or series and indicates the primary alloy(s). A capital letter preceding the numerical description refers to modifications made to specific alloys. Aluminum castings end in “.0”.

In commercial specifications, aluminum alloys are usually divided into three categories: pure aluminum alloys, heat treatable alloys and non-heat treatable alloys.