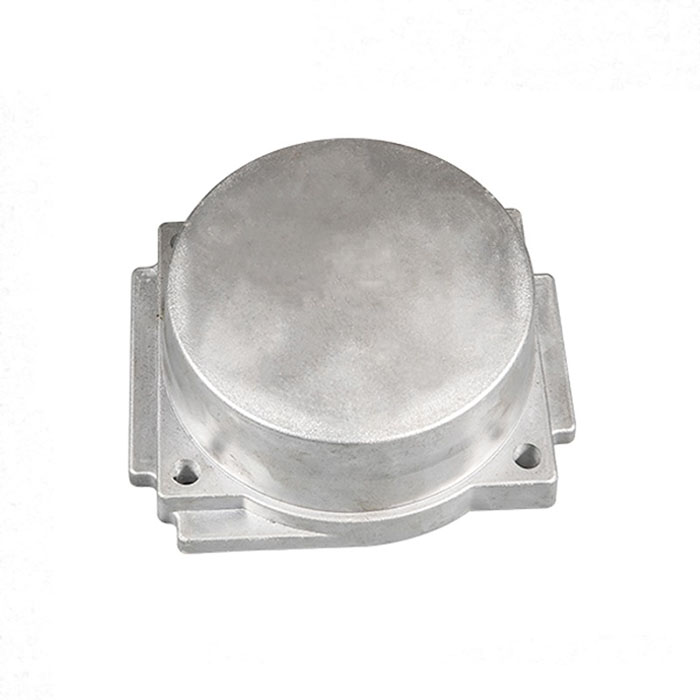

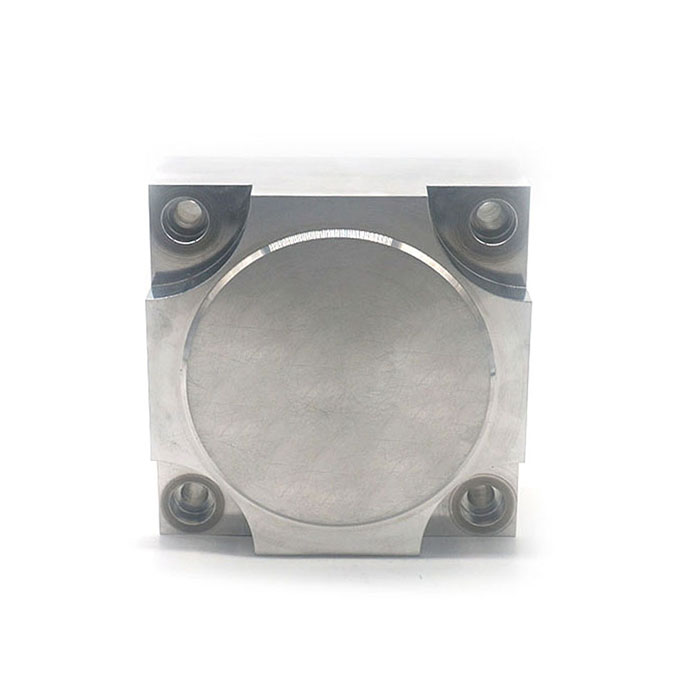

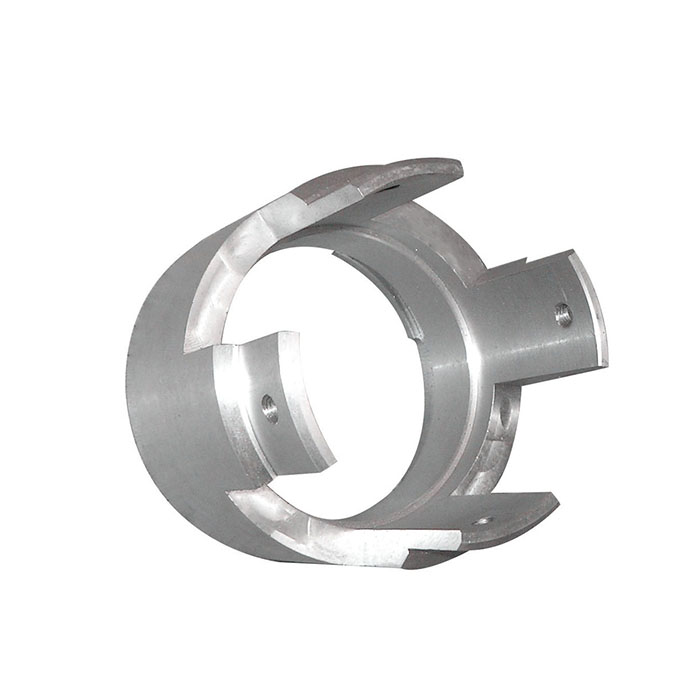

Casting Product: Cast Iron Caster Wheel, Gray Iron Trundle, Ductile Iron Truckle, Transformer Casting Parts Application Information: The caster wheel is used for transformer device. A caster is a wheeled device typically mounted to a larger object that enables relatively easy rolling movement of the object. Material Grades: Gray Cast Iron, Grey Iron, Cast Iron ISO185 GRADE 100, 150, 200, 250, 300 USA ASTM A48 CLASS NO.20, NO.25, NO.30, NO.35, NO.40, NO.45 GERMANY DIN1691 GG10, GG15, GG20, GG25, GG30 EURO EN1561 EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300 UK BS1452 100, 150, 180, 200, 220, 250, 260. 300 AUSTRALIA AS1830 T150, T180, T200, T220, T250, T260, T300 CHINA GB HT100, HT150, HT200, HT250, HT300 Ductile Cast Iron, S.G. Iron, Ductile Iron, Nodular Cast Iron, Spheroidal Graphite Cast Iron ISO1083 400-15, 400-18, 450-10, 500-7, 600-3, 700-2 USA ASTMA536 60-40-18, 60-42-10, 65-45-12, 70-50-05, 80-55-06, 80-60-03, 100-70-03 GEAMANY DIN1693 GGG40, GGG50, GGG60, GGG70 EURO EN1563 EN-GJS-400-15, EN-GJS-400-18, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2 UK BS2789 400/17, 420/12, 500/7, 600/3, 700/2 AUSTRALIA AS1831 370-17, 400-12, 500-7, 600-3, 700-2 CHINA GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2 Casting Production Equipment: Sand Casting, Automatic Molding, Machine Molding, Shell Molding, Green Sand Casting, Resin Sand Casting, Medium Frequency Electric Furnace Casting Supplier: Iron Foundry in China, Cast Iron Foundry, Iron Casting Manufacturer, China Foundry, Chinese Foundry Foundry Introduction: We have complete quality inspection devices for Mechanical Testing, Chemical Analysis, and Non-destructive Inspection, including tensile strength, hardness, metallographic inspection, spectrometer, ultrasonic testing (UT), etc. Our foundry has ISO 9001 & TS 16949 quality certificates, and we can issue quality inspection reports for all castings. Quality Control is always our most important work.

Experience

Casting Product: Cast Iron Caster Wheel, Gray Iron Trundle, Ductile Iron Truckle, Transformer Casting Parts Application Information: The caster wheel is used for transformer device. A caster is a wheeled device typically mounted to a larger object that enables relatively easy rolling movement of the object. Material Grades: Gray Cast Iron, Grey Iron, Cast Iron ISO185 GRADE 100, 150, 200, 250, 300 USA ASTM A48 CLASS NO.20, NO.25, NO.30, NO.35, NO.40, NO.45 GERMANY DIN1691 GG10, GG15, GG20, GG25, GG30 EURO EN1561 EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300 UK BS1452 100, 150, 180, 200, 220, 250, 260. 300 AUSTRALIA AS1830 T150, T180, T200, T220, T250, T260, T300 CHINA GB HT100, HT150, HT200, HT250, HT300 Ductile Cast Iron, S.G. Iron, Ductile Iron, Nodular Cast Iron, Spheroidal Graphite Cast Iron ISO1083 400-15, 400-18, 450-10, 500-7, 600-3, 700-2 USA ASTMA536 60-40-18, 60-42-10, 65-45-12, 70-50-05, 80-55-06, 80-60-03, 100-70-03 GEAMANY DIN1693 GGG40, GGG50, GGG60, GGG70 EURO EN1563 EN-GJS-400-15, EN-GJS-400-18, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2 UK BS2789 400/17, 420/12, 500/7, 600/3, 700/2 AUSTRALIA AS1831 370-17, 400-12, 500-7, 600-3, 700-2 CHINA GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2 Casting Production Equipment: Sand Casting, Automatic Molding, Machine Molding, Shell Molding, Green Sand Casting, Resin Sand Casting, Medium Frequency Electric Furnace Casting Supplier: Iron Foundry in China, Cast Iron Foundry, Iron Casting Manufacturer, China Foundry, Chinese Foundry Foundry Introduction: We have complete quality inspection devices for Mechanical Testing, Chemical Analysis, and Non-destructive Inspection, including tensile strength, hardness, metallographic inspection, spectrometer, ultrasonic testing (UT), etc. Our foundry has ISO 9001 & TS 16949 quality certificates, and we can issue quality inspection reports for all castings. Quality Control is always our most important work.